.jpg)

.jpg) |

-Not Enough Bonding Performance |

| -Easy to Cause Cracking On Brake Pads | |

| -Not Suitable for High Speed Road Driving | |

| -Not Enough For Heavy Load Trucks | |

| -Can't Guarantee Your Safey During Driving |

|

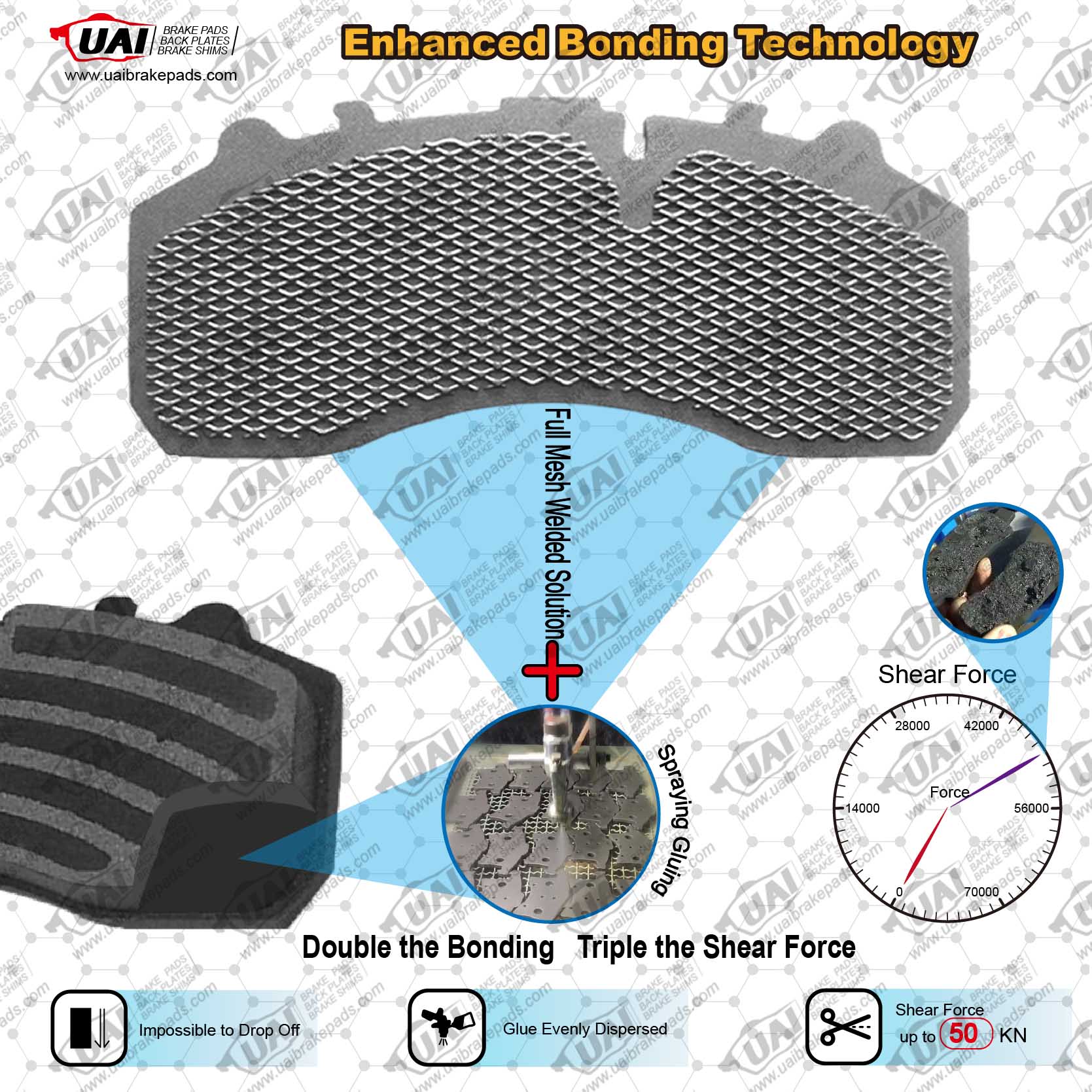

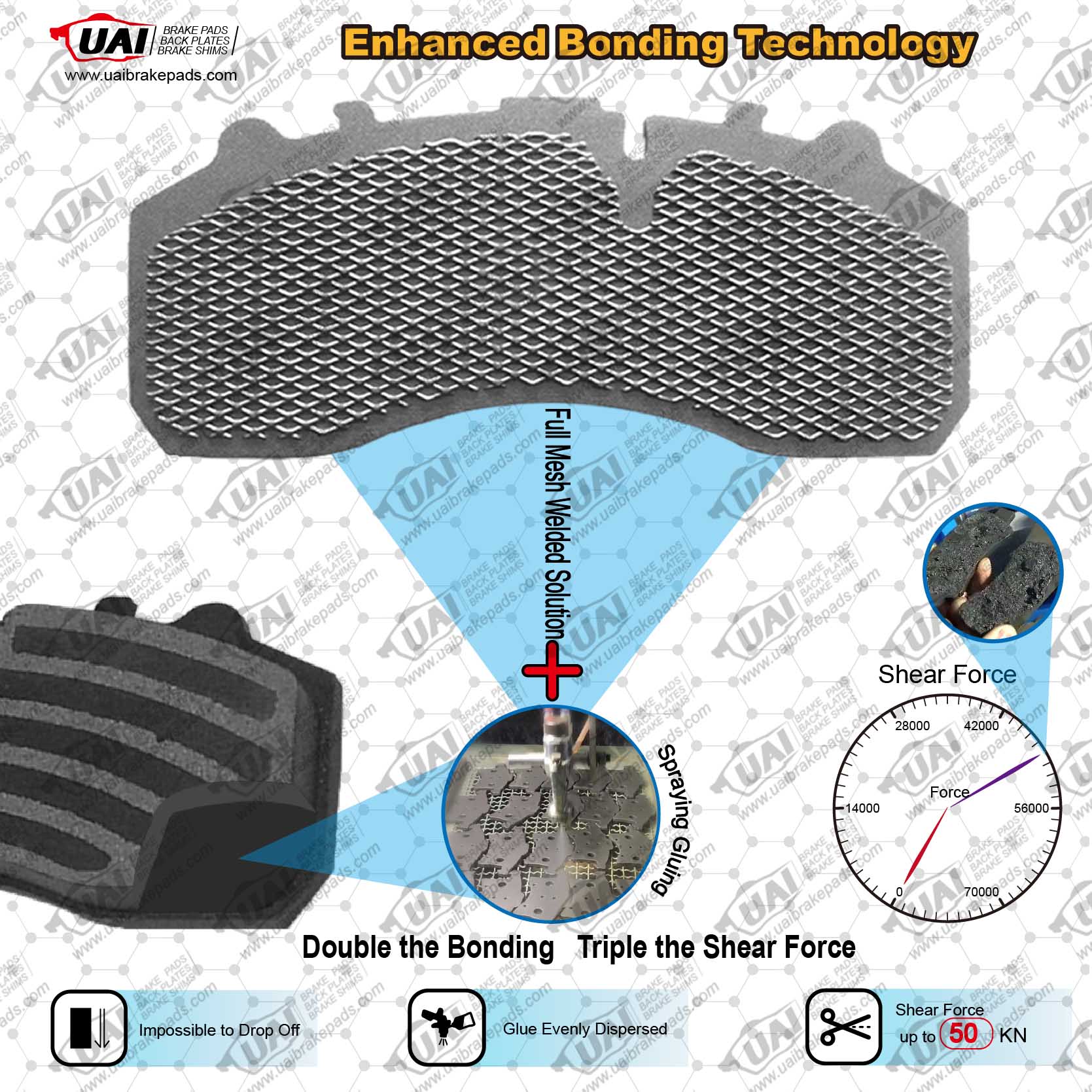

-Higher Shear Force, Keeps Your Safety |

| -Stronger Bonding Performance Between Friction Materials and Backing Plates | |

| -OE Standards Quality Control | |

| -ECE R90 Certificated | |

| -Long Working Life of Brake Pads | |

| -Premium Braking Performance |

|

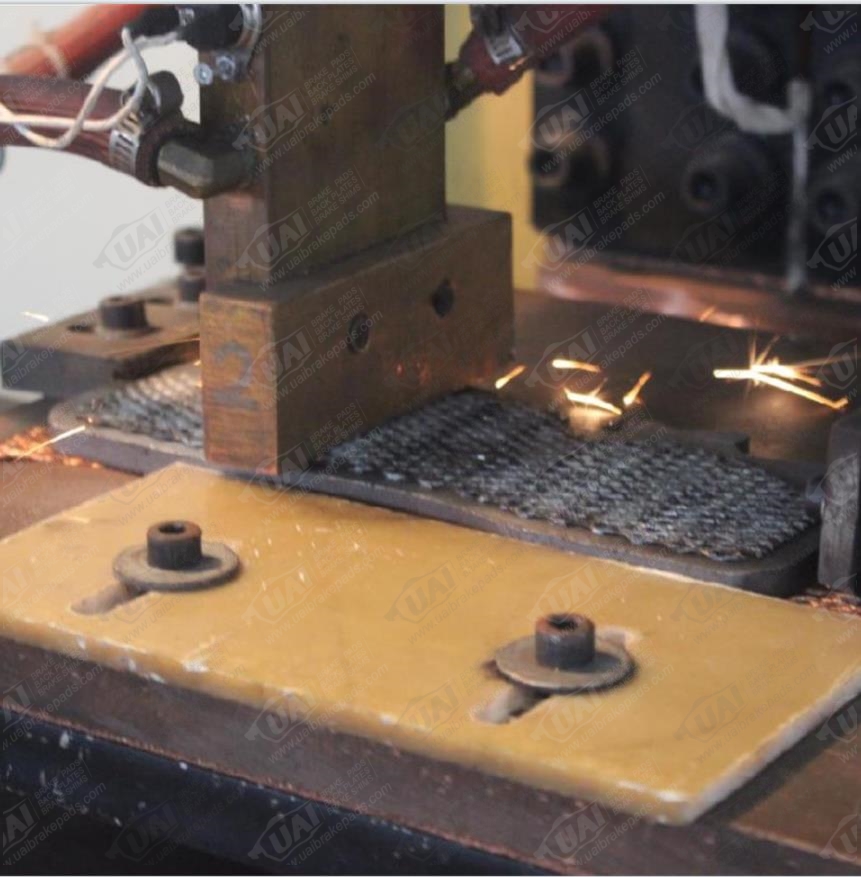

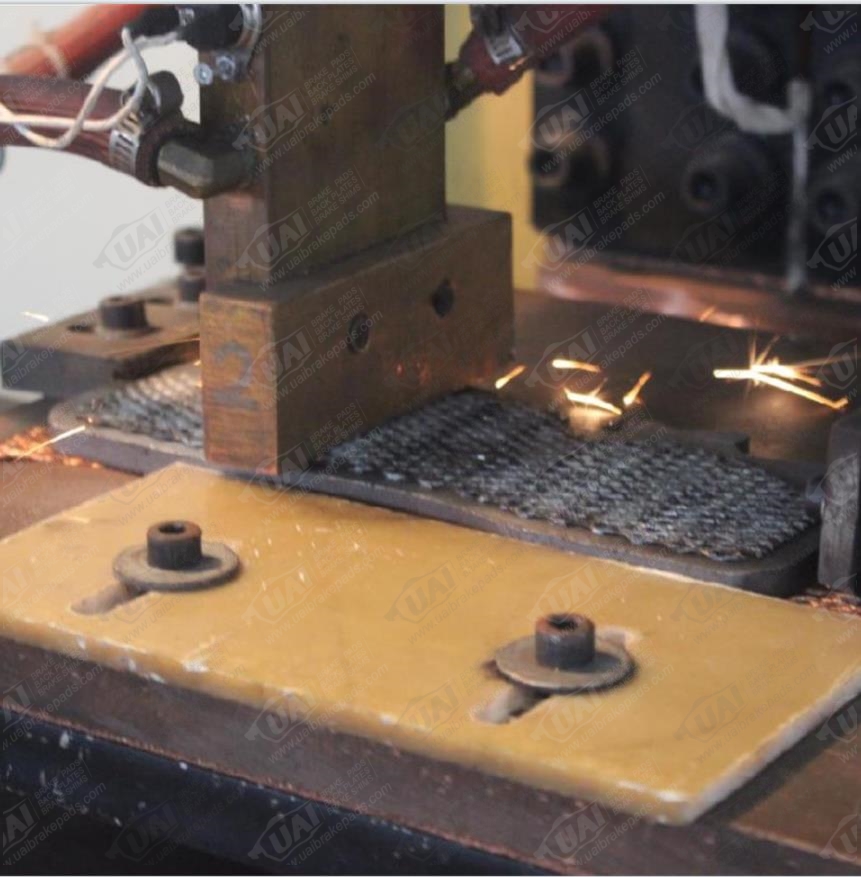

-Full Automatic Production Process |

| -Stable Welding Performance | |

| -100% Mesh Area Welding | |

| -Higher Bonding Between Steel Mesh and Back Plates | |

| -OE Quality Guaranteed |

1. Using high-quality Q235B carbon steel, with high yield points at 235MPa, no possible to bend during the braking.

2. Thickness is uniform, flatness is controlled within 0.1-0.2mm;

3. Quality is stable and consistent.

4. Molds are manufactured according to the FMSI standard drawings;

5.Strictly produced, accurate size to match for the OE brake capilers and brake discs;

6. Perfectly fit in the caliper, thus reduce the noise caused by friction with the caliper accessories during braking.

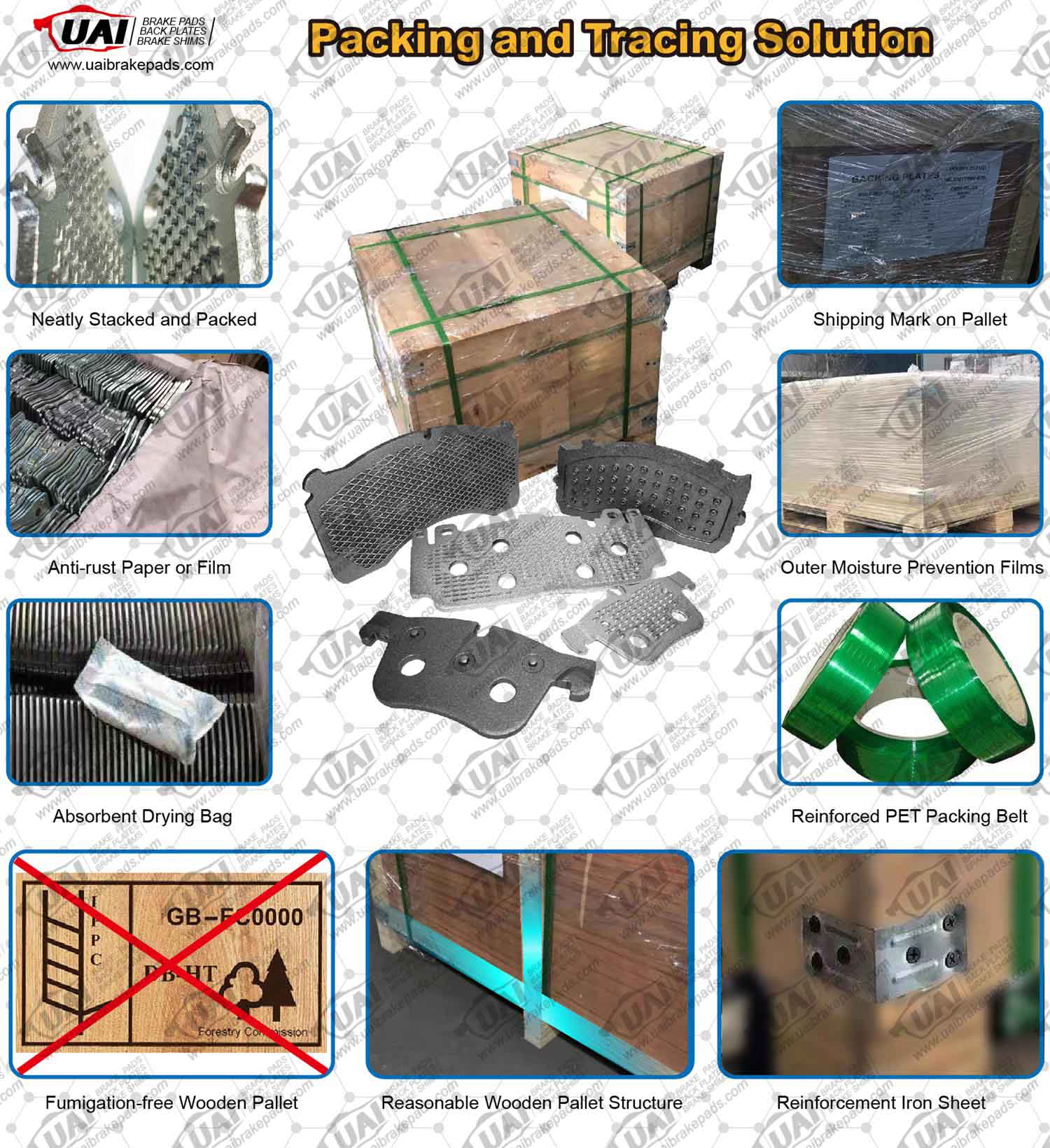

All the backing plates will be neatly stacked into a wooden pallet, if backing plates with hooks, they will be stacked hooks to hooks to prevent the outer surface scratch.

All the backing plates will be wrapped with anti-rust paper or film to prevent from moisture during the sea or air transportation.

Besides the anti-rust paper or film, absorbent drying bags will also be put into the pallet to absorb moisture during the transportation.

The raw material of the fumigation-free pallet is composite board or plywood, and the raw material is formed by high-temperature and high-pressure sterilization of various wooden residual materials.

The wooden box adopts a reinforced structure, and there are reinforced wooden boards all around. The structure is optimized to make the whole wooden box more reasonable and firm, and it is not easy to fall apart and break.

There is iron sheet reinforcement around the wooden pallet to prevent it from falling apart due to the heavy steel backing plates.

After packing, the whole pallet will use Reinforced PET Packing Belt to make a third protection.

At last, the whole pallet will be covered by moisture prevention films to stop the rain or water during transportation in the first stage.

There will be a shipping mark on each pallet for sea transportation and logistic purposes, also easy for you to trace and identify.

We export about 300 Containers Each Year, Every Container Will Be Delivered To Customer's Hands Safely and Timely.

Contact:Julie Yu

Mobile:+8613967121799

Email:sales@uaibrakepads.com

Address:No. 1136, East Tiaoxi Road, Qianyuan Town,Deqing County, Huzhou City,Zhejiang Province, China